Please Wait ...

Please Wait ...

Enquiry

Curently We are Not Serviceable In this Pincode

91 Springboard, Business Hub, Godrej & Boyce, Gate No. 2, LBS Marg, Vikhroli West, Mumbai, 400079

91 Springboard, Business Hub, Godrej & Boyce, Gate No. 2, LBS Marg, Vikhroli West, Mumbai, 400079

91 Springboard, Business Hub, Godrej & Boyce, Gate No. 2, LBS Marg, Vikhroli West, Mumbai, 400079

91 Springboard, Business Hub, Godrej & Boyce, Gate No. 2, LBS Marg, Vikhroli West, Mumbai, 400079

91 Springboard, Business Hub, Godrej & Boyce, Gate No. 2, LBS Marg, Vikhroli West, Mumbai, 400079

91 Springboard, Business Hub, Godrej & Boyce, Gate No. 2, LBS Marg, Vikhroli West, Mumbai, 400079

91 Springboard, Business Hub, Godrej & Boyce, Gate No. 2, LBS Marg, Vikhroli West, Mumbai, 400079

91 Springboard, Business Hub, Godrej & Boyce, Gate No. 2, LBS Marg, Vikhroli West, Mumbai, 400079

91 Springboard, Business Hub, Godrej & Boyce, Gate No. 2, LBS Marg, Vikhroli West, Mumbai, 400079

Min

Max

₹5,000

₹45,000

Suggested Price

Blogs> The Science Behind Refurbished Appliances: How They’re Restored to Like-New Condition

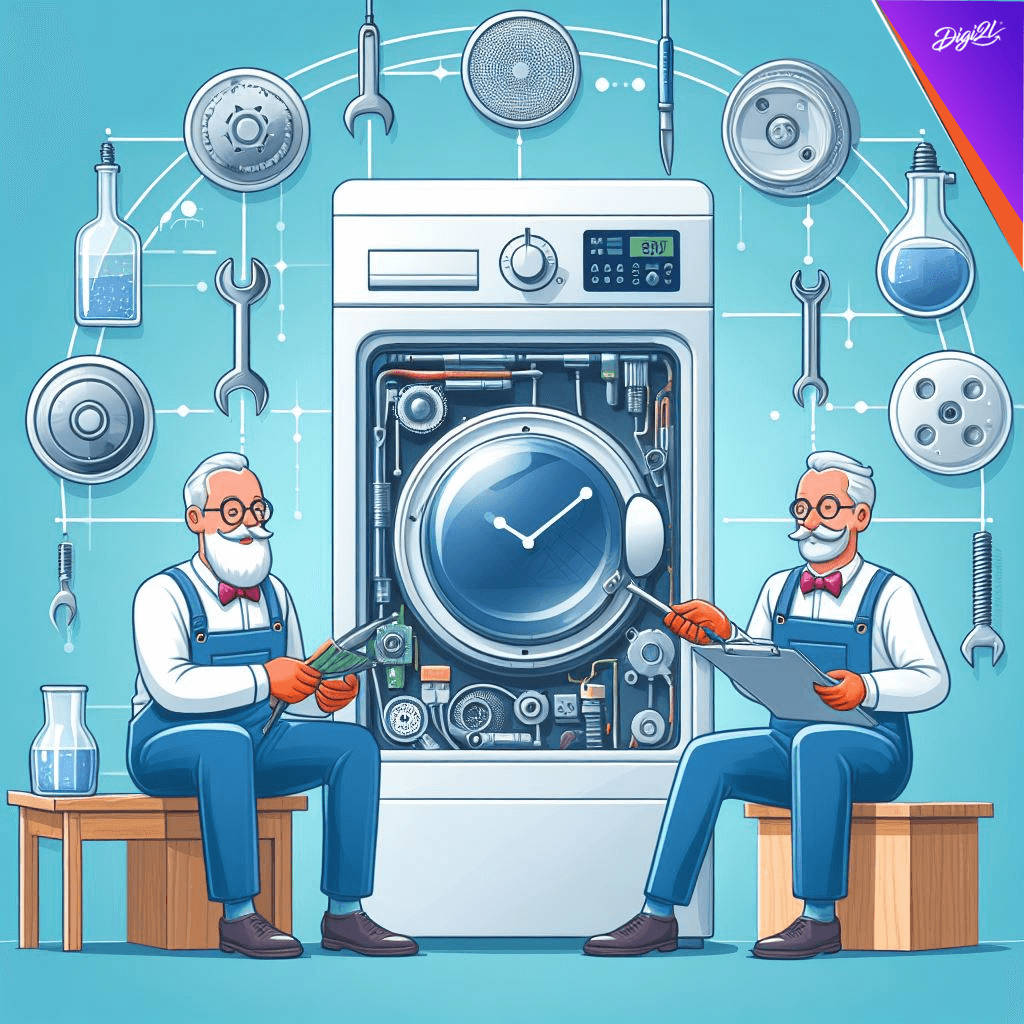

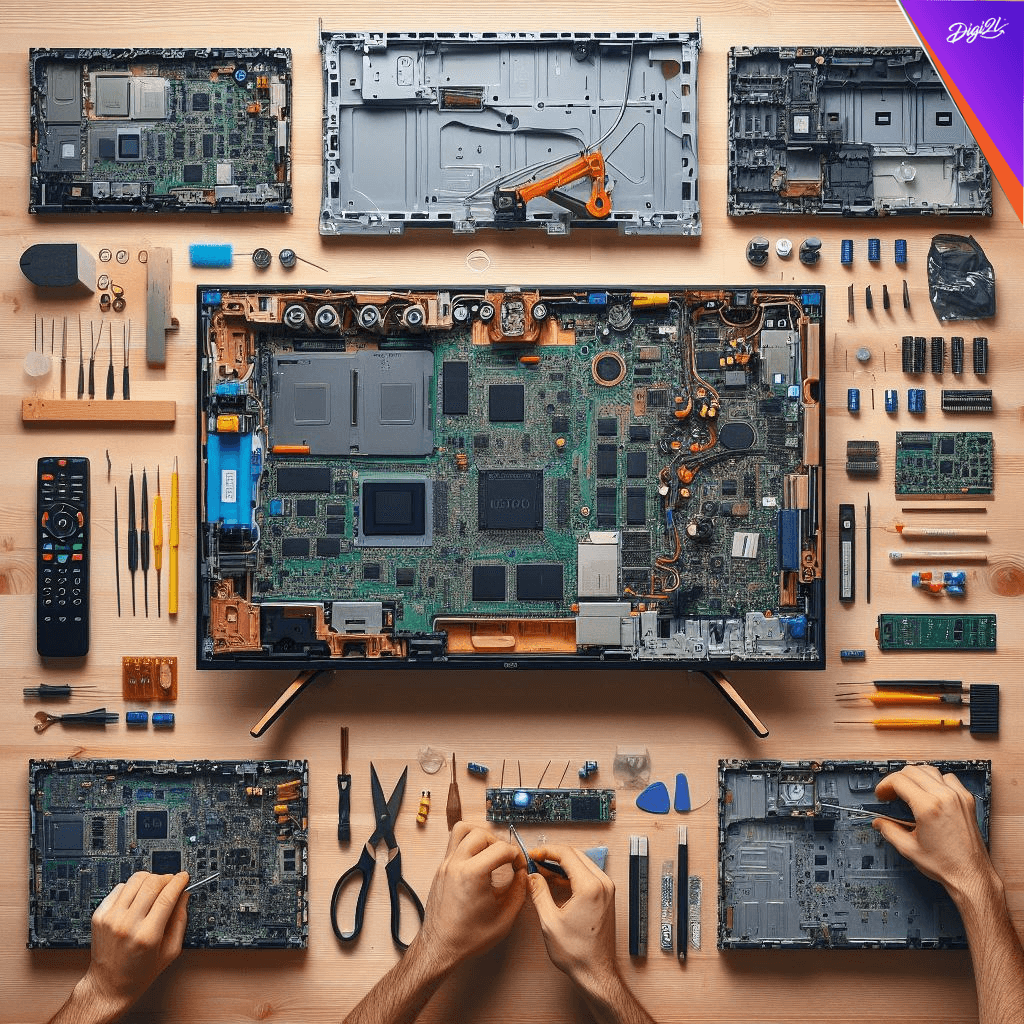

Refurbished appliances undergo a rigorous 14-step quality check process to restore them to like-new condition. This includes sourcing, thorough diagnosis, deep cleaning, sanitization, reconditioning with OEM parts, tightening connections, extensive testing, record-keeping, calibration, and final inspection. Each appliance is carefully packaged with detailed documentation and clear communication of results. Explore our range of refurbished appliances—like refrigerators, washing machines, televisions, and air conditioners—for quality and value at affordable prices, while supporting sustainability.

In recent years, the market for refurbished appliances has gained traction as consumers seek cost-effective and sustainable alternatives to purchasing new items. Refurbished appliances, including refrigerators, washing machines, televisions, and air conditioners, undergo a meticulous restoration process to ensure they perform like new. At the heart of this transformation, Digi2L makes sure a comprehensive 14-step quality check that integrates advanced technology and skilled craftsmanship. Let’s delve into the science behind refurbishing and how these appliances are rejuvenated to meet high-quality standards.

In conclusion, the process of refurbishing appliances is a blend of science and craftsmanship. From sourcing to final inspection, each step is meticulously executed to breathe new life into pre-owned appliances. This not only offers consumers an affordable alternative but also contributes to sustainability by reducing waste. If you’re in the market for appliances, consider the benefits of buying refurbished—saving money while minimizing environmental impact.

If you’re looking to buy refurbished appliances, explore Digi2Lstore.com for a range of quality appliances including refrigerators, washing machines, televisions, and air conditioners. Discover the science behind refurbishment and experience the value of like-new appliances without the hefty price tag. Make the smart choice today—choose refurbished.

By Digi2L - April 29, 2024

By Digi2L - April 28, 2024

By Digi2L - April 27, 2024